Strain Gauges

|

|

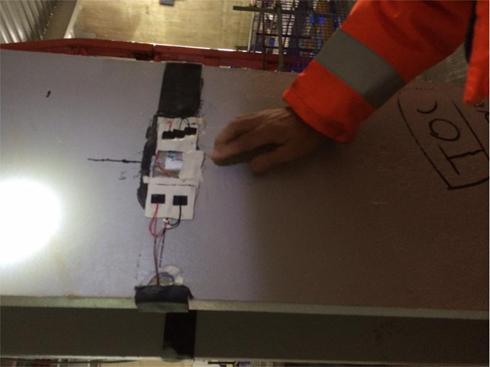

Stain gauge installation services for monitoring stress within a bridge structure or building during jacking operations. They take advantage of the physical material properties of either compression or tension, strain gauges measure electrical resistance of the internal wire length in proportion to any stress applied.

The most accurate method of monitoring change in resistance, is the use of Wheatstone bridge networks. This allows a balanced electrical circuit to display any change throughout the indicator.

The main area where Hydra-Capsule integrate these strain gauges are on the below applications:

- For monitoring structures such as bridges and structural buildings.

- Monitoring load within a temporary propping system.

- Within all types of load cells.

Strain-Gauge Load Cell for Temporary Propping Systems

Hydra-Capsule have developed and designed their own in-house strain-gauge propping section load cells. Tested, calibrated within our technical test press workshop. Which gives the ability to monitor load (and change) remotely or in-situ on all temporary propping systems applications.

This can be positively used in fatigue studies of materials, in sensors measuring deformation (for example, across a bridge by loading positions and effects) in engineering, in other calculations of all sorts of physical distortions proportional to loading or thermal environments. |

|

|

|

|

|

|