Grout Bags for Underpinning

Grout bags used for underpinning operations are manufactured from a specially woven fabric which enables them to withhold relatively high pressures when inflated with grout. A simple yet practical device used when conventional shutters are impossible to fit the grout bag can be adopted to provide a quick and easy solution.

Download technical data information sheet from download page.

Once pressurised the contact surfaces form a perfect bearing area regardless of shape. They are normally used for a multitude of applications, such as; underpinning foundations, dry-packing alternative, support beam preloading device, temporary or permanent packs (chocks) for supports.

We offer an extensive standard range available off the shelve listed below:

Alternatively, we can manufacture special sizes to suit your particular application or project. However, please remember that specials made to order can take time, sometimes up to eight weeks depending on the quantity required. Our standard lightweight hand operated grout pumps and electric paddle mixers are also available for hire or sale at competitive rates.

We strongly recommend that customers use our non-shrink 'Hydra-Grout' which has very high flow properties making it easy and efficient to pump when using our light weight hand operated grout pumps. The material has been specially formulated for use with our products, it obtains high strengths quickly, (20 N/mm2 within 24 hours and 55 N/mm2 within 7 days) while also maintaining a reasonable working period during installation (45 minutes), for further advice or assistance please contact us.

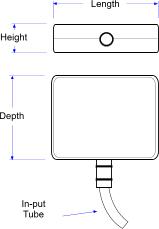

RECTANGULAR TYPE

|

| MODEL CODE |

LIFTING CAPACITY

(tonnes) |

CURED CAPACITY

(tonnes) |

BAG DEPTH

(mm) |

BAG LENGTH

(mm) |

MAXIMUM HEIGHT

(mm) |

MAXIMUM

PRESSURE |

BAG VOLUME

|

FILLED WEIGHT |

| GB-101 |

0.7 |

30 |

150 |

250 |

50 |

4 bar |

2.2 lts |

4 kgs |

| GB-102 |

1.1 |

40 |

200 |

300 |

50 |

4 bar |

3.5 lts |

7 kgs |

| GB-103 |

1.6 |

50 |

250 |

350 |

75 |

4 bar |

7.5 lts |

14 kgs |

| GB-104 |

2.2 |

75 |

300 |

400 |

75 |

4 bar |

10.5 lts |

19 kgs |

| GB-105 |

2.7 |

100 |

350 |

450 |

100 |

4 bar |

18.4 lts |

34 kgs |

| GB-106 |

3.6 |

125 |

400 |

500 |

100 |

4 bar |

23.4 lts |

43 kgs |

| GB-107 |

4.5 |

150 |

450 |

550 |

125 |

4 bar |

36.2 lts |

66 kgs |

| GB-108 |

5.4 |

200 |

500 |

600 |

125 |

4 bar |

43.9 lts |

80 kgs |

| GB-109 |

6.5 |

250 |

550 |

650 |

150 |

4 bar |

62.8 lts |

114 kgs |

| GB-110 |

7.2 |

300 |

600 |

700 |

150 |

4 bar |

73.7 lts |

134 kg |

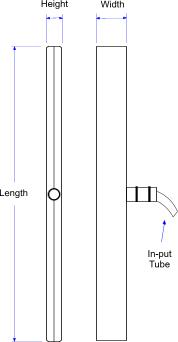

BEAM TYPE

|

| MODEL CODE |

LIFTING CAPACITY

(tonnes) |

CURED CAPACITY

(tonnes) |

BAG DEPTH

(mm) |

BAG LENGTH

(mm) |

MAXIMUM HEIGHT

(mm) |

MAXIMUM

PRESSURE |

BAG VOLUME |

FILLED WEIGHT |

| GB-201 |

0.8 |

25 |

100 |

500 |

50 |

4 bar |

2.5 |

7 kgs |

| GB-202 |

1.7 |

50 |

100 |

1000 |

50 |

4 bar |

5.0 |

12 kgs |

| GB-203 |

2.6 |

75 |

100 |

1500 |

50 |

4 bar |

7.5 |

16 kgs |

| GB-204 |

3.5 |

100 |

100 |

2000 |

50 |

4 bar |

10.0 |

21 kgs |

| GB-205 |

4.4 |

125 |

100 |

2500 |

50 |

4 bar |

12.5 |

25 kgs |

| GB-206 |

7.8 |

160 |

150 |

3000 |

75 |

4 bar |

33.8 |

64 kgs |

| GB-207 |

9.2 |

250 |

150 |

3500 |

75 |

4 bar |

39.4 |

75kgs |

| GB-208 |

10.5 |

300 |

150 |

4000 |

75 |

4 bar |

45.0 |

86 kgs |

| GB-209 |

11.2 |

350 |

150 |

4500 |

75 |

4 bar |

50.6 |

95 kgs |

| GB-210 |

13.1 |

400 |

150 |

5000 |

75 |

4 bar |

56.6 |

106 kgs |

| GB-211 |

19.3 |

500 |

200 |

5500 |

100 |

4 bar |

110.2 |

204 kgs |

| GB-212 |

21.1 |

600 |

200 |

6000 |

100 |

4 bar |

120.1 |

223 kgs |

| GB-213 |

22.7 |

700 |

200 |

6500 |

100 |

4 bar |

130.2 |

241 kgs |

| GB-214 |

25.0 |

800 |

200 |

7000 |

100 |

4 bar |

140.1 |

259 kgs |

| GB-215 |

26.7 |

900 |

200 |

7500 |

100 |

4 bar |

150.3 |

277 kgs |

Hydra-Grout Quality per 25 kgs Bag = 20 Litres

GIVING CONSTRUCTION OUR SUPPORT

|

|