Flat Jacks and Flat Jacking Systems

Flat jacks ranging from 8 to 1,030 tons in capacity, the ultra low unit is capable of exerting extremely high trust forces. They are normally used within the civil and construction industry for a multitude of jacking applications, such as, lifting heavy structures, stressing operations, transferring existing loads / pre-loading steelwork to temporary or permanent supports and permanently pre-loading bearings, bridge jacking and structures.

Technical data sheet for

flat jacking brochure applications can be loaded from

download page for relative information.

Due to their design, our flat jacking equipment is not only light in weight but require a minimal installation gap or just a few centimetres. When selecting a flat jack, the ideal working range should be about 75% to 85% of the flat jacks capacity.

All our Hydra Capsule flat jacks are fully designed and manufactured within our new purpose built warehouse facility. Where we test all flat jacking equipment to the maximum specified force / load within our 1200 tonnes test press, submitted with full proof loading certification.

Permanent Units for Preloading New Steelworks

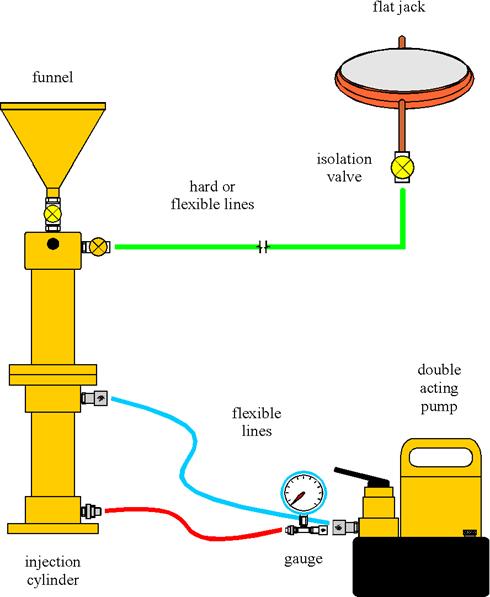

Flat jacks have the ability to induce a permanent force/load required for pre-loading steelwork and a structure respectively. The installation of our flat jacking equipment is carried out in-situ and inflated using a high pressure injection system, epoxy resin or cementitious grout can be injected, but grout filled units are normally recommended in order to meet the current day environmental and fire regulations.

This

application is normally implemented to

new supporting steelworks during structural alterations, underpinning or bridge bearing replacement operations requiring pre-stressing to avoid excessive deflections taking place when any temporary supports are removed.

It’s essential that the flat jacking grouting operation is carried-out quickly and efficiently and we would therefore strongly recommend that our experienced flat jack engineers carry out such operations as mistakes can prove to be expensive.

Hydra-Capsule provide a full design, in-house manufacturing and flat jack

installation service offered throughout the UK and Internationally. Bespoke units can also be manufactured to suit customers particular requirements, please contact us for further details.

Advantages:

- Permanently induced force.

- Known and precise load induction.

- Used for alternative load cells applications

- Balance force loading for flat jacking multiple sets.

- Temporary to permanent using transfusion techniques.

- Monitoring of loads during building construction.

|

|

|

|

Flat Jacks from 8 to 868 Tons Capacity

|

|

JACK

CODE |

CAPACITY

(tons) |

CLOSED HEIGHT |

OUTSIDE

DIAMETER |

THRUST

DIAMETER |

MAXIMUM

STROKE |

MAXIMUM

PRESSURE |

FLUID

LITRES |

WEIGHT

(KGS) |

Data

Sheet |

| FJ 12 |

8 |

28 |

120 |

75 |

25 |

150 bar |

0.3 |

4 |

.png) |

| FJ 15 |

15 |

29 |

150 |

105 |

25 |

150 bar |

0.5 |

8 |

.png) |

| FJ 17 |

20 |

29 |

170 |

125 |

25 |

150 bar |

0.8 |

9 |

.png) |

| FJ 19 |

25 |

30 |

190 |

145 |

25 |

150 bar |

1.1 |

10 |

.png) |

| FJ 22 |

40 |

30 |

220 |

175 |

25 |

150 bar |

1.2 |

16 |

.png) |

| FJ 25 |

50 |

30 |

250 |

205 |

25 |

150 bar |

1.3 |

19 |

.png) |

| FJ 27 |

60 |

31 |

270 |

225 |

25 |

150 bar |

1.6 |

20 |

.png) |

| FJ 30 |

80 |

32 |

300 |

254 |

25 |

150 bar |

1.9 |

23 |

.png) |

| FJ 35 |

100 |

34 |

350 |

304 |

25 |

150 bar |

2.6 |

26 |

.png) |

| FJ 42 |

160 |

35 |

420 |

373 |

25 |

150 bar |

3.6 |

29 |

.png) |

| FJ 45 |

180 |

36 |

450 |

403 |

25 |

150 bar |

4.1 |

30 |

.png) |

| FJ 48 |

210 |

36 |

480 |

433 |

25 |

150 bar |

4.7 |

32 |

.png) |

| FJ 52 |

265 |

36 |

520 |

473 |

25 |

150 bar |

5.7 |

36 |

.png) |

| FJ 56 |

300 |

37 |

560 |

512 |

25 |

150 bar |

6.2 |

38 |

.png) |

| FJ 60 |

345 |

38 |

600 |

553 |

25 |

150 bar |

7.4 |

43 |

.png) |

| FJ 75 |

600 |

36 |

750 |

705 |

35 |

150 bar |

12.4 |

89.5 |

.png) |

| FJ 87 |

764 |

40 |

870 |

825 |

35 |

150 bar |

16.8 |

110.8 |

.png) |

| FJ 92 |

868 |

40 |

920 |

875 |

35 |

150 bar |

18.7 |

126.4 |

.png) |

| FJ 102 |

1030 |

55 |

1020 |

940 |

40 |

150 bar |

24.4 |

175.2 |

.png) |

| Each individual jack is fully proof load tested and certified as in accordance with UK legislation. |

|

|

Temporary Flat Jacks for Bridge Jacking

When flat jacks are required for a temporary duration and then subsequently removed, they are normally inflated using water or hydraulic oil.

The benefits of temporary flat jacks:

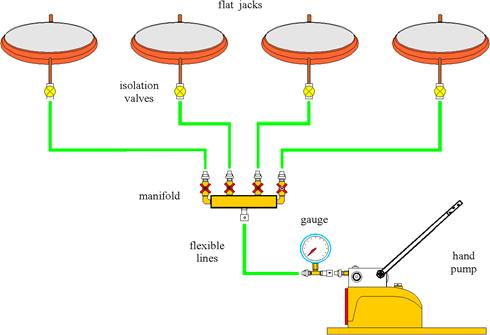

- Used as load cells when connected to pressure gauge or transducer complete with digital read-outs.

- Pre-loading steelwork with temporary support systems

- Continuous load monitoring and adjustment possible.

- Multiple flat jack circuit to enable uniform loading.

- Ability to transfuse from temporary to permanent.

Transfusion Units

Single Flat Jack

Transfusion flat jacks are specially designed in-house, and manufactured by Hydra-Capsule, they have the ability to transfuse grout whilst under load, from a temporary to a permanent load. The design of the flat jacks allows for a balanced load and movement displacement throughout the grout transfusion operation. Which are ideal for the use of bridge jacking projects.

Due to our purpose built manufacturing facility, we are able to offer fully modifications for vertical and horizontal transfusion jacks for all necessary requirements.

Double-Stack

The same can be achieved as the double-stack arrangement, however, the transfusion method is inflating one flat jack while the other is deflated while maintaining a constant balanced load between both flat jacks.

GIVING CONSTRUCTION OUR SUPPORT